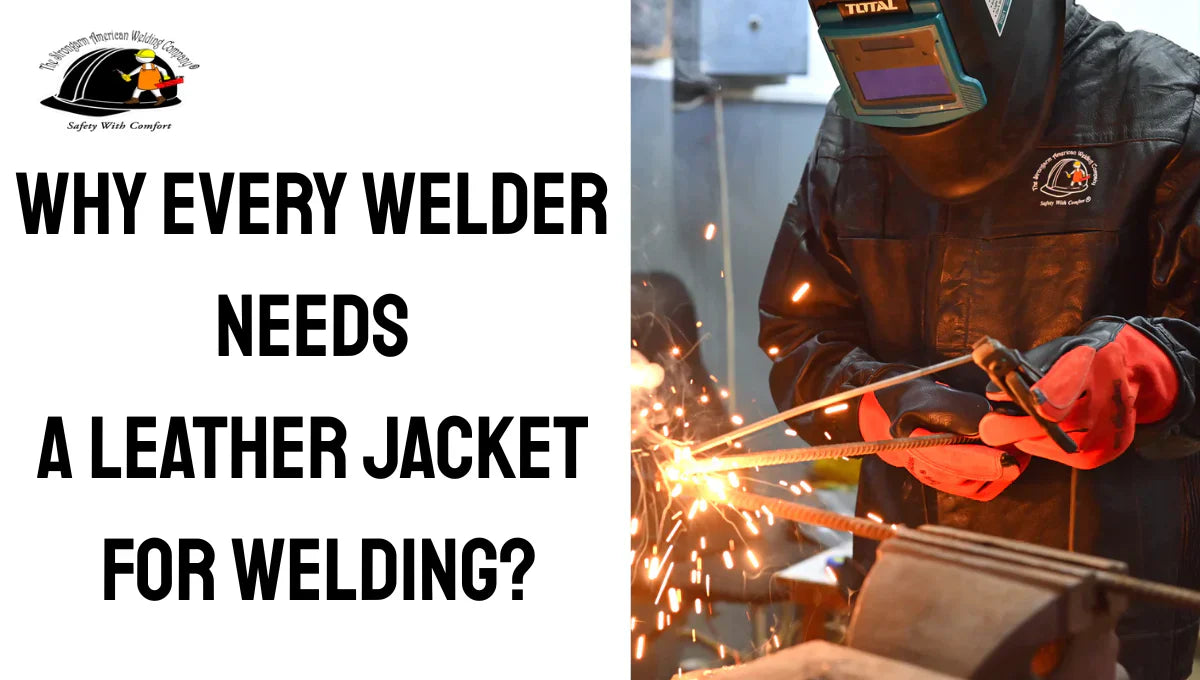

The welding environment is full of hazards; sparks fly, heat intensifies, and spatter can cause injuries within seconds. While helmets and gloves protect specific areas, a leather jacket for welding delivers complete upper-body protection against heat, sparks, and molten metal. For professionals and hobby welders alike, it is one of the most reliable layers of safety. The StrongArm Welding ensures you can focus on precision instead of worrying about burns or accidents.

The Role of Protective Gear in Welding

Every welder understands that protection is not optional; it is essential. Exposure to flying sparks, radiant heat, and ultraviolet radiation can lead to severe injuries. Ordinary cotton shirts or synthetic fabrics melt quickly and can even worsen injuries by sticking to the skin.

This is where specialized welding jackets stand apart. Designed with fire-resistant properties and reinforced durability, they act as a shield, making welding safer and more efficient. Whether you work in heavy fabrication or occasionally do home repairs, the right jacket plays a critical role in your safety.

Leather Jacket for Welding: Key Benefits

Among all protective gear, our welding Jackets remains the gold standard. Leather is naturally resistant to heat and spatter, offering welders superior durability compared to cotton or synthetic fabrics.

Key benefits include:

- Maximum Heat Resistance: Leather withstands prolonged exposure to sparks and spatter.

- Durability: A well-made leather jacket lasts for years under demanding conditions.

- Full Coverage: Protection extends across the torso, shoulders, and arms.

- Confidence While Working: Welders can focus on precision instead of distractions from heat or burns.

By combining strength and comfort, the best welding jacket ensures welders work with both safety and confidence.

Types of Welding Jackets

Not all welding jackets are built the same, and understanding the types of welding jackets helps welders make informed decisions.

- Leather Welding Jackets: Designed for heavy-duty tasks, these jackets offer maximum resistance to sparks, flames, and high heat. They are ideal for industrial environments where durability and protection matter most.

- FR Cotton Jackets: Flame-resistant cotton jackets provide lightweight protection for light-duty welding. One popular choice is the FR Welding Jacket – Green (30"), which balances safety with breathability.

- Hybrid Welding Jackets: A mix of leather sleeves with FR cotton torso, offering both comfort and targeted protection.

For welders seeking premium protection, the Premium Black FR Jacket combines heavy-duty safety with a professional look, making it one of the most trusted choices in demanding work environments.

Why Choose StrongArm Welding Jackets?

Professionals trust StrongArm Welding because every product is built with a commitment to safety, performance, and reliability. Welders who rely on our jackets know they are investing in more than clothing; they are choosing dependable protection.

- Proven Safety: Designed to withstand sparks, flames, and heat.

- Durable Build: Jackets are reinforced to last in industrial settings.

- Comfortable Fit: Ergonomic designs allow free movement without compromising safety.

- Trusted by Professionals: StrongArm’s reputation is built on consistent quality and customer trust.

For welders comparing the types of welding jackets, StrongArm provides solutions for every need, from the lightweight FR Welding Jacket – Green (30") to the heavy-duty Premium Black FR Leather Welding Jacket.

How to Choose a Welding Leather Jacket

When you set out to choose leather jacket, several factors determine the right fit:

- Job Type: For industrial environments with heavy spatter, leather is unmatched. For light fabrication, FR cotton may be sufficient.

- Fit and Mobility: Jackets must allow free movement while still covering vulnerable areas.

- Climate and Comfort: In warmer environments, a hybrid jacket balances breathability with safety.

- Longevity: A leather jacket for welding is an investment that pays off with years of reliable service.

Maintenance Tips for Welding Jackets

Proper maintenance ensures your welding jacket lasts longer and performs reliably:

- Cleaning: Brush off metal dust and spatter regularly. Avoid harsh detergents.

- Storage: Keep in a cool, dry place away from direct sunlight.

- Inspection: Check seams and closures frequently to ensure integrity.

- Conditioning Leather: Use recommended leather conditioners to maintain flexibility.

By caring for your jacket, you not only extend its life but also maintain its protective qualities.

Customer Testimonials

Anthony J. – Structural Welder, Illinois

"The Premium Black FR Leather Welding Jacket from StrongArm is the most durable jacket I’ve ever owned. It protects me from heavy sparks and still feels comfortable to wear all day."

Maria S. – Fabrication Supervisor, California

"I ordered the FR Welding Jacket – Green (30") for my team, and it’s been excellent for lighter welding work. Breathable, protective, and long-lasting. StrongArm gear never disappoints."

Kevin L. – Pipeline Contractor, Oklahoma

"StrongArm jackets are built tough. Mine has handled months of heavy MIG welding without a single issue. The quality and fit give me total confidence at work."

FAQs

Q1: What is the best welding jacket for heavy-duty work?

The best option for heavy-duty tasks is a full Leather Welding Jacket, as it offers maximum resistance to sparks, spatter, and high heat, making it ideal for MIG and stick welding.

Q2: Are FR cotton welding jackets safe enough?

Yes, FR cotton jackets like the FR Welding Jacket – Green (30") are safe for light to medium-duty welding. They provide flame resistance and breathability but are not as long-lasting as full leather jackets.

Q3: Why choose the Premium Black FR Leather Welding Jacket?

The Premium Black FR Leather Welding Jacket combines strong fire resistance, durability, and a professional look, which makes it a trusted choice for industrial welders who want both safety and style.

Q4: How do I select the right welding jacket?

Your choice depends on the job. A Leather Welding Jacket is best for high-heat industrial work, an FR cotton jacket is suitable for lighter tasks, and a hybrid jacket is ideal for welders who need breathability with targeted leather protection.

Q5: How should I maintain my leather welding jacket?

To extend the life of your jacket, brush off debris after each use, store it in a cool dry place, use leather conditioner to maintain flexibility, and regularly inspect seams and closures for durability.

Final Thoughts

For anyone serious about welding, investing in a leather jacket for welding is non-negotiable. It provides safety, durability, and confidence that lighter fabrics cannot match. Whether you prefer the lightweight FR Welding Jacket – Green (30"), the heavy-duty Premium Black FR Leather Welding Jacket, or another option among the many types of welding jackets, StrongArm Welding has a solution designed with your safety in mind.