Welding is an essential process in many industries, but it can be risky for the welder. Welding aprons provide vital protection from heat, sparks, and spatter. However, there are protective garments to safeguard the wearer from any damage. These gaments must meet strict safety standards, have the right certifications, and have clear labeling to ensure they comply with welding apron safety standards. This guide explores welding apron safety standards, certifications, and labeling to help welders make informed choices and stay safe in hazardous welding environments.

Welding Apron Safety Standards

Organizations like the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA) have set several safety standards to ensure welding aprons effectively protect workers. These standards cover design, materials, and performance requirements for welding aprons. The goal is to enhance safety and durability in various welding environments. Key aspects of choosing a safe welding apron safety standards include:

Material Durability

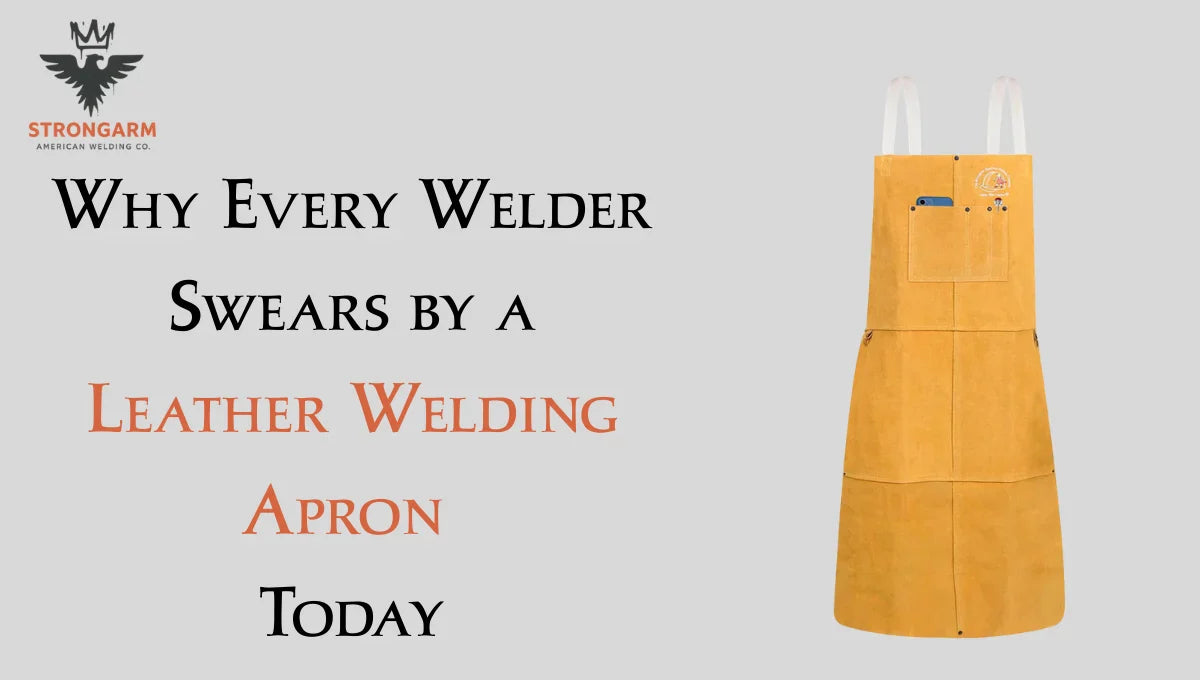

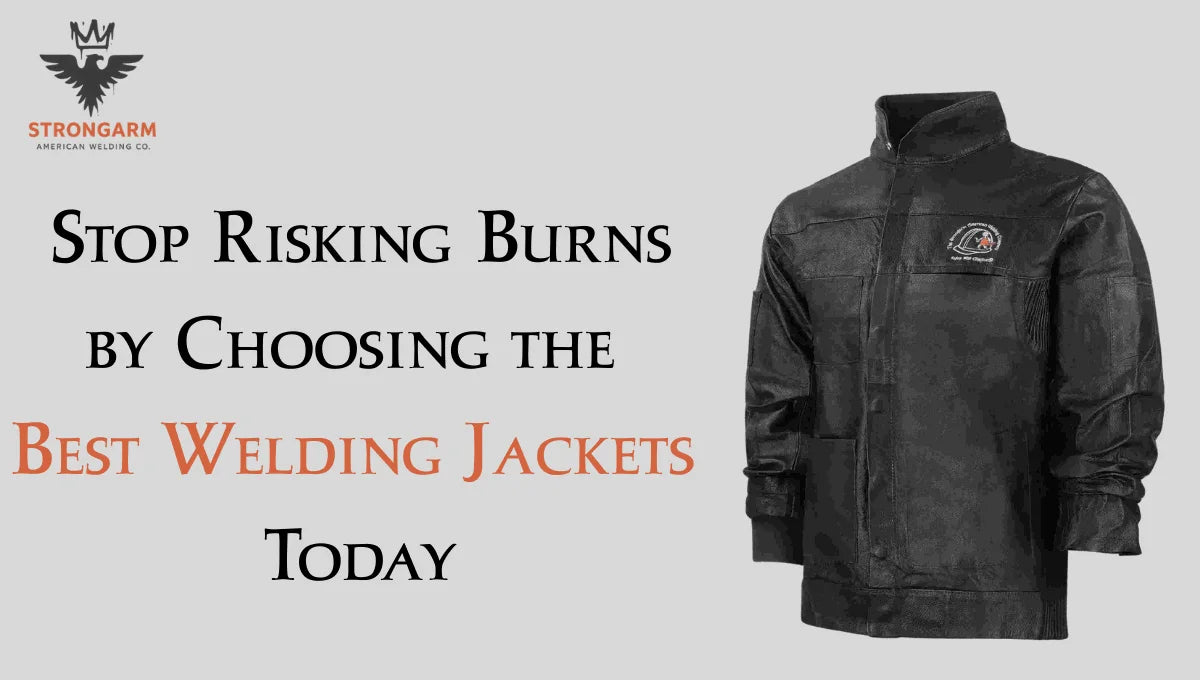

Welding aprons must be constructed from flame-resistant properties in welding aprons that can withstand high temperatures without igniting or melting. Common materials used include leather, treated cotton, and fire-retardant fabrics.

Coverage and Fit

Welding aprons should provide adequate coverage to protect the torso and upper legs, with adjustable straps for a secure and comfortable fit. Proper fit ensures unrestricted movement while maintaining full coverage during welding operations.

Resistance to Sparks and Splatter

Welding aprons must effectively repel sparks, slag, and molten metal splashes to prevent burns and injuries. The material should have a smooth surface to facilitate the easy removal of debris and to avoid adherence to hot particles.

Heat Insulation

Welding aprons need to keep the wearer safe from the heat produced during welding. They can do this by having multiple layers or special panels that provide extra heat protection while allowing the wearer to move quickly.

Certifications and Labeling

To attest to the compliance of welding aprons with safety standards, manufacturers often seek certifications from accredited testing laboratories. These certifications validate the performance and quality of welding aprons, assuring users of their reliability in hazardous work environments. Common welding apron certifications explained include:

ANSI/ISEA 105

The American National Standards Institute (ANSI) oversees the development of safety standards for personal protective equipment, including welding aprons. ANSI/ISEA 105 certification indicates that the apron meets stringent flame resistance, thermal protection, and durability criteria.

NFPA 70E

The National Fire Protection Association (NFPA) standard 70E establishes workplace electrical safety guidelines, including arc flash protection. While not specific to welding aprons, compliance with NFPA 70E ensures that the apron offers adequate protection against arc flash hazards commonly encountered in welding operations.

CE Marking

The CE marking signifies compliance with European Union (EU) safety standards, including those applicable to personal protective equipment (PPE). Welding aprons bearing the CE mark meets the requirements outlined in relevant EU directives, guaranteeing a certain level of user protection.

EN ISO 11611

EN ISO 11611 certification indicates compliance with specific European standards for welding aprons, covering aspects such as material quality, design, and performance.

UL & SFI

UL and SFI ratings provide additional assurance of safety and performance for welding aprons. UL focuses on safety testing and certification, and SFI offers standards specific to the automotive and racing industries.

In addition to certifications, welding aprons are often labeled with essential information regarding their performance and care instructions. This labeling typically includes:

Material Composition

Indicates the fabric or leather used in the apron's construction and any specialized flame resistance or heat insulation treatments.

Flame Resistance Rating

Rating specifies the apron's level of flame resistance, usually expressed as the duration during which the fabric can withstand direct exposure to flames without ignition.

Care and Maintenance Guidelines

This section offers recommendations for cleaning, storage, and inspection to prolong the apron's lifespan and ensure its continued effectiveness.

Conclusion

Welding aprons are crucial for protecting the health and safety of welders in various industrial settings. By following welding apron safety standards and obtaining reputable certifications, employers can provide their workforce with reliable protective gear that can withstand the demands of welding operations. Certifications and labeling empower employers and workers to make informed decisions when choosing welding aprons, ultimately reducing the risk of injuries and promoting a culture of workplace safety.

FAQS

What does EN ISO 11611 certification mean for welding aprons?

EN ISO 11611 certification indicates that a welding apron meets the specific safety requirements for protective clothing used in welding and related processes. This includes testing for heat resistance, flame spread, and durability under various conditions typical of welding environments.

How can I identify if a welding apron is flame-resistant (FR)?

Flame-resistant welding aprons will be labeled as FR, which should be indicated on the product tag or label. Look for certifications and test results that confirm the material's FR properties. Manufacturers often provide details on the level of flame resistance in their product descriptions.

Why are third-party certifications important for welding aprons?

Third-party certifications, such as those from UL or SFI, provide an independent verification of the welding apron's compliance with stringent safety standards. These certifications assure that the apron has undergone rigorous testing and meets established safety criteria, offering an extra layer of trust in the product's quality and effectiveness.

Are there reputable brands known for high-quality welding aprons?

Several reputable brands are known for producing high-quality welding aprons that meet or exceed safety standards. Some well-regarded brands include Strongarm, Tillman, Lincoln Electric, Miller, and Revco. These brands are recognized for their commitment to safety, durability, and comfort in their protective gear.